Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

To Study the Mechanical Properties of Concrete Using Coconut Fibre Ash & CRT Powder with Addition of Asbestos Fiber

Authors: Sumer Singh, Sourabh Lalotra

DOI Link: https://doi.org/10.22214/ijraset.2024.65730

Certificate: View Certificate

Abstract

One of the ongoing issues with global sustainability in the twenty-first century is concrete. Cement has the highest carbon dioxide emissions and energy consumption of all the components used in concrete, which include water, fine aggregates, cement additives, and cement itself. Cathode-Ray Tube (CRT) technology has fallen behind as new technologies like Liquid Crystal Displays (LCD) and LED Display Panels are constantly replacing it. As a result, there are more CRTs that need to be disposed of annually worldwide. It can modify the physical property of concrete. Use and Recycling of CRT Tube also reduce environmental hazard. Coconut coir fiber ash in concrete construction is an alternative of cement, coconut fiber ash has a good tendency when uses as a partial replacement for cement. Cement being costly material, so if partially replaced by coconut fiber ash can reduces the cost of concrete. The heat of hydration is decreased, which help in improving the drying, shrinkage and facilitate durability of the concrete mix. Coconut Fiber Ash has a tendency to increase Compressive, tensile, and flexural strength. Asbestos fibers were historically used as an additive in concrete to enhance its properties, primarily its tensile strength and resistance to cracking. The mechanical qualities of concrete, such as its tensile strength, durability, and fire resistance, were successfully improved with asbestos fibers. Because of this, asbestos-reinforced concrete gained popularity in the middle of the 20th century for a variety of building uses. This project\'s aim is to stop environmental damage caused by inappropriate disposal by employing it as an additional material in specially developed by Coconut Fiber Ash and CRT. The 11% of Coconut Fiber Ash and CRT powder replace with cement and with addition of 0.8% Asbestos fibers. Fiber were used as reinforcement. The compression strength test, flexural strength test, and split tensile strength test were used to determine the maximum proportion of replacement.

Introduction

I. INTRODUCTION

Ordinary Portland cement (OPC) is currently regarded as the most important building material in the world. The conformist building material that actually contributes between 5% and 8% of carbon dioxide emissions worldwide is Portland cement. The material should be valued if it can replace cement entirely or even if it can replace cement partially by providing the necessary amount of strength. Cement is known to be used primarily second to water worldwide and to produce a significant amount of carbon dioxide in the atmosphere. The environmental impact of cement may expand significantly if the demand for it grows exponentially. Today, researchers worldwide are focusing on various use of agricultural or industrial waste as essential industrial resources. In addition to being economical, it could aid in the reduction of environmental contamination. In order to create ecological building materials, the Portland cement industry is looking into alternatives.

A. Asbestos Fibre

The word asbestos is derived from a Greek word meaning "indestructible." It is the common name for a group of fibrous silicate minerals, the most common of which are chrysotile, crocidolite and amosite. Asbestos can extinguish fires even at extremely high temperatures and is extremely flexible and durable. Asbestos is a common term referring to six types of naturally occurring mineral fibres used or commercially used. These fibres belong to two groups of minerals: serpentine and amphiboles. The serpentine group contains one type of asbestiform: chrysotile. As asbestos fibres are all silicates, they exhibit other common elements, such as insulation, thermal stability, resistance to natural heat, chemical inertia directed at multiple chemicals, and low energy efficiency [4]. The standard definition of asbestos fibre does not include many other fibrous minerals that may have an asbestiform pattern but do not reflect all asbestos structures.

B. Cathode Ray Tube (CRT)

A Cathode Ray Tube (CRT) is the glass video display component of an old electronic video device. Reuse or repair of these tubes are not practical options, CRTs can be recycled. Due to the presence of lead located in the funnel glass, CRTs marked for disposal are considered hazardous waste. CRTs and CRT glass were once easily recycled into new CRTs. However, the demand for new CRTs has collapsed in favour of new flat panel technologies. Because of rising costs, negative economic incentives and shifts in CRT glass markets, some CRT processors and recyclers are choosing to store the glass indefinitely rather than send it for recycling or disposal, which increases the risk of mismanagement and/or abandonment of CRTs.

C. Coconut Coir Fiber Ash

The use of coconut fibers which is the most versatile in class of other natural fibers has a great significance as reinforcing material in concrete. It is easily decomposable and therefore having less influence on environmental condition and replacing them with cement is the best way to dispose of the coconut fiber. Using the natural fiber as the replacement in concrete has reduced the main factor of civil industry which is High Cost.

Coconut coir fiber ash in concrete construction is an alternative of cement, coconut fiber ash has a good tendency when uses as a partial replacement for cement. Use of Coconut fiber ash is eco-friendly as the waste materials from industries and agriculture are being used for the formation of quality concrete. Coconut Fiber Ash has a tendency to increase Compressive, tensile, and flexural strength. High-performance Concrete. It act as Insulator in concrete.

II. LITERATURE REVIEW

Bhupendra Kumar 2015 This study assesses the usage of fly ash and coconut fiber in concrete of M40 grade. Cement was substituted with fly ash at 10%, 20%, and 30%. Coconut fibers (0.25-1.0 cm in diameter, 4 cm in length) were added in different amounts. While the results demonstrated minor gains when CFA and fly ash were applied separately, the combined usage of both additives resulted in enhanced compressive strength. Increased fiber content resulted in decreased workability.

Okere Chinenye Elizabeth 2019 In this experimental study, CFA was used at 0%–25% in place of cement. The findings showed that while compressive strength peaked at 10% replacement, workability declined as the CFA concentration increased. Beyond this, strength decreased as the amount of ash increased.

Chaudhary, et al (2017)) The most used building material is concrete, which has very poor shear, tensile, and cracking qualities. Fiber Reinforced Concrete (FRC) is a novel building material that was created after extensive research and development to create these facilities. Concrete's compressive strength properties and flexible strength were assessed using a variety of test years, including 7, 14, and 28 days. The design of M 30 level concrete complies with IS 10262-2009. By AFRC concrete volume, the fiber addition ranged from 0.33 percent to 0.66%, 1.0%, 1.33%, 1.66%, and 2.0%. The highest AFRC compression strength was achieved with a fiber addition of 0.33%. The test findings indicate that while the AFRC's flexibility has significantly increased, its compressive strength has only marginally improved.

Bouharoun, et al (2014) aimed to study the feasibility of using fibre-cement asbestos waste instead of standard Portland cement to produce mud. Fibre-cement particles were dipped in the 14 mud to partially add cement, with replacement rates in quantities of 5 and 20%. The level of Cement hydration, efficiency, total deceleration, access slope and water-based mortar and mortar systems were measured compared to the control structures attached to the cement (free by fibre cement). The results showed that fibre-cement availability increased 5-10% of the remaining binder hydration time, compared to that of Portland cement, depending on the replacement rate shown. In addition, within 28 days, 5 and 20% fibre-cement replacement caused a 14-35% decrease in compressive strength, compared to the cement production of reference. This drop was greater than what was seen in the mud containing limestone filler with the same level of cement. However, the available energy was acceptable in the use of the building.

Hilton et al. 2019 in his suggested that CRT glass pozzolana recycled in concrete at 20% by weight cement replacement yields a significant benefit in concrete and confirms that it is a lower carbon material with cementitious properties for the higher energy cement and it will also decrease the overall environmental impact of the cement.

Kim et al. 2018 Replaced the fine aggregated of concrete with waste CRT funnel Heavy weight glass and suggested that concrete mixes with heavyweight waste glass show excellent durability, thus can be used in radiation shielding structures. The slump value was increased as the waste glass substitution ratio increased, air content was increased slightly as the waste glass content increased. The decrease in the compressive and flexural strength could be increased by using low water cement ratio and low air content.

III. MATERIALS

A. Cement

As the primary limiting material in this investigation, Ordinary Portland Concrete 43 evaluation—sulfate obstruction with normal warmth of hydration—was used. Concrete is a material used for construction that confines various components together by setting, solidifying, and holding them in place. Sometimes concrete is used to bond sand and rock (total) together rather than all by itself. Concrete is used with sand and rock totals to deliver concrete, or with fine total to make mortar for brick work. The process of making conventional Portland cement (OPC) involves grinding a mixture of limestone and other fixes, such as gypsum, calcareous, and argillaceous.

B. Coarse Aggregates

The coarse totals used in this analysis were machine-made and occasionally fit as a glove. The use of smasher totals in this analysis is justified by the fact that their compressive quality is significantly higher than that of regular totals, and that their flaky appearance influences the proper official of the solid blend's constituents, thereby improving the structure's quality and durability. Grading of coarse aggregate was done according to IS:383-1970. Aggregates of Nominal size 20mm & 10mm to form a graded aggregate. The concerned lab provided the properties of coarse aggregate.

B. Fine Aggregates

In this investigation, the best available nature of fine total has been used. The fine total used was sand that was collected from the Jhelum stream and acquired by a waterway. Stream sand is a fine total obtained from a waterway, while machine sand is a fine total obtained from a machine. The sand was subjected to the subsequent tests in order to determine its quality and qualities. Sieve analysis would be done to find out the zone conforming IS: 383-1970. The physical properties of sand were provided by the concerned lab.

D. CRT

CRTs are carefully dismantled to separate the glass parts from electronic components. This replacement might be used in projects such as creating durable structures or alternative construction materials, leveraging CRT glass combined with cement for sustainability. Grinding to finer particles Improves the reactivity and binding when mixed with cement. Coating the particles with materials like silanes can improve bonding with cement. Fine CRT powder can react with calcium hydroxide in the cement to enhance strength and durability.

Table no. 1 Properties of CRT

|

Sr |

Chemical Component |

Typical Composition (% by Weight) |

|

1 |

Silica (SiO?) |

40–60% |

|

2 |

Lead Oxide (PbO) |

20–30% |

|

3 |

Aluminum Oxide (Al?O?) |

5–10% |

|

4 |

Sodium Oxide (Na?O) |

5–10% |

|

5 |

Potassium Oxide (K?O) |

1–5% |

|

6 |

Calcium Oxide (CaO) |

2–8% |

|

7 |

Barium Oxide (BaO) |

1–5% |

|

8 |

Magnesium Oxide (MgO) |

1–3% |

E. Asbestos Fibre

Asbestos is a common term referring to six types of naturally occurring mineral fibres used or commercially used. These fibres belong to two groups of minerals: serpentine and amphiboles. The serpentine group contains one type of asbestiform: chrysotile. There are five types of asbestiform amphiboles: anthophyllite asbestos, grunerite asbestos (amosite), riebeckite asbestos (crocidolite), tremolite asbestos, and actinolite asbestos. Usually, the word asbestos is used only for those types used for commercial purposes. As asbestos fibres are all silicates, they exhibit other common elements, such as insulation, thermal stability, resistance to natural heat, chemical inertia directed at multiple chemicals, and low energy efficiency

Table no. 2 Properties of AF

|

S. No |

Physical Properties |

Description |

|

1 |

Fiber Structure |

Long, thin, flexible fibers with high aspect ratio. |

|

2 |

Diameter |

0.1 to 10 microns. |

|

3 |

Length |

Varies, often much longer than its diameter. |

|

4 |

Tensile Strength |

Extremely strong, resistant to breaking under tension. |

|

5 |

Flexibility |

Can bend without breaking; suitable for weaving. |

|

6 |

Heat Resistance |

Withstands temperatures up to 1,000°C (1,832°F). |

|

7 |

Property |

Description |

F. Coconut Fiber Ash

To make coconut fiber ash, coconut husk fibers are gathered and burned to produce a fine, ash-like residue. The first step involves gathering and preparing dried coconut husks, which are frequently regarded as agricultural trash. To guarantee full combustion, the fibers are subsequently burned at high temperatures (usually between 600 and 800°C) in a controlled setting, such as an open pit, furnace, or kiln. An ash that is high in silica and other minerals is left behind after the organic components of the fibers are decreased during the burning process. After cooling, the ash is meticulously gathered, sieved to get rid of bigger, unburned particles, and, if necessary, crushed into a fine powder. The resultant ash from coconut fibers is frequently utilized as a soil amendment in agriculture, an additional cementitious ingredient in the construction of concrete or as a raw material in other industries due to its pozzolanic properties and environmental sustainability.

Table no. 3 Properties of CFA

|

Description |

||

|

Color |

Gray to dark gray (depending on combustion conditions). |

||

|

Texture |

Fine powder after sieving and grinding. |

||

|

Particle Size |

Typically ranges from 1 to 50 microns. |

||

|

Bulk Density |

Around 1.2 to 1.5 g/cm³ (varies with combustion process). |

||

|

Specific Gravity |

Approximately 2.3 to 2.6. |

||

|

Porosity |

Moderate, due to fine particle size. |

||

|

Thermal Stability |

High resistance to thermal decomposition. |

IV. METHODOLOGY

A. Mixing Concrete

All the ingredients of concrete are mixed together however this mix should be homogenous and uniform in color and consistency. The mixing can either be done by hand or with the use of mixer.

B. Mixing Concrete

Thorough mixing of the materials is essential to produce uniform concrete. The mixing should make sure that the mass become homogeneous, uniform in consistency and colour. There are two methods adopting for mixing concrete one is hand mixing and other is machine mixing.

C. Curing

Before removing the mould, it is dried for 24 hours, and then specimens are placed in a water tank made to cure specimens. The specimens must be marked for identification so that there must not be any error. The specimens are removed from the tank and dried before putting in the testing machine. The specimens are kept in the tank for 7,14,28 days.

D. Workability Test

It can be used in site as well as in lab. This test is not applicable for very low and very high workability concrete. It consists of a mould that is in the form of frustum having top diameter of 10cm, bottom diameter of 20cm and height of 30cm. The concrete to be tested if fitted in the mould in four layers. The each is compacted 25 times with the help of tamping rod. After the mould is completely filled it is lifted immediately in the vertically upward direction which causes the concrete to subside.

Fig -1: SLUMP CONE TEST

E. Compressive Strength Test

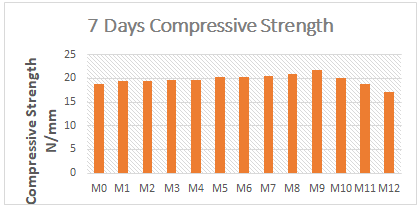

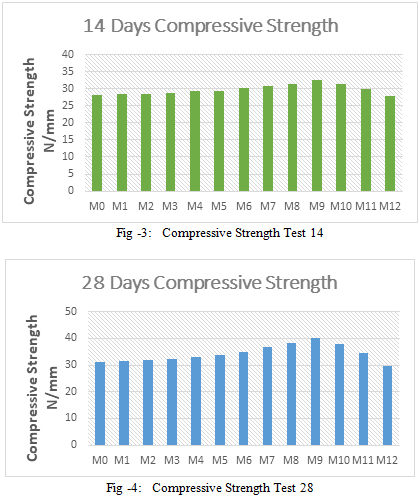

Then fresh concrete is filled in mould in 4 layers and after filling each layer tamping should be done 35 times in case of cube and 25 times in case of cylinder by using standard tamping rod. Once the mould is filled then leveled top surface of concrete with trowel. After the day the mould will removed and specimen are dropped in the curing tank under standard temperature of 27±2° c. After 7,14 days and 28 days in this research.

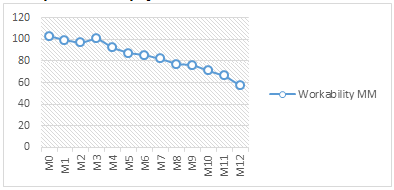

Fig -2: Compressive Strength Test 7

F. Split Tensile Strength Test

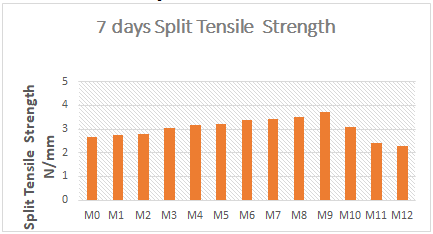

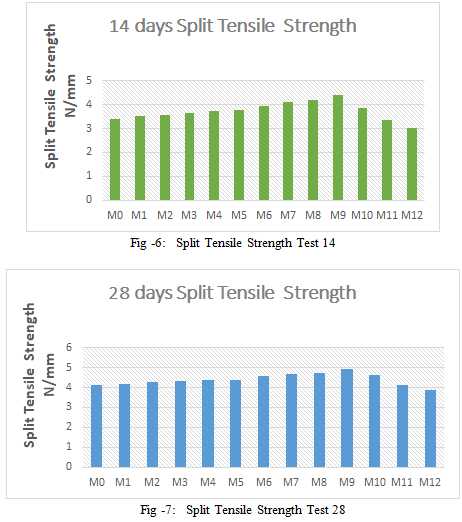

The specimen used for this test is cylindrical and its dimension is 150 mm in diameter and 300mm in length. The instrument used for this testing is universal testing machine. The fresh concrete is prepared in according to the required grades and respective mix proportion. The fresh concrete is filled in mould in layers and each layer is tamping with standard tamping rod with 25 blows for each layer. After the day the mould is removed and specimen is placed in the curing tank for 7,14 days and 28 days in this research at the temperature 27+ 2°c. Then draw the line on the specimen.

Fig -5: Split Tensile Strength Test 7

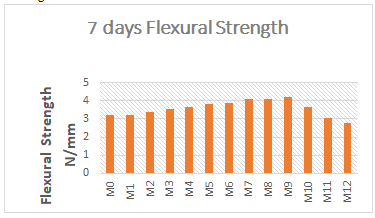

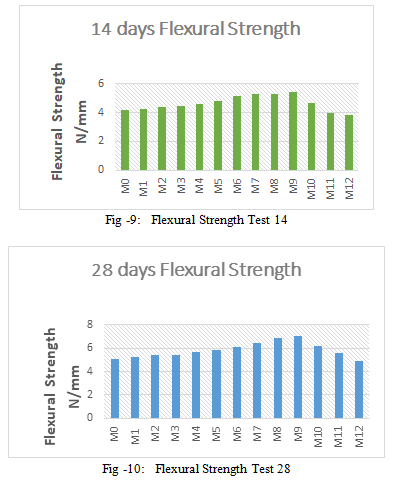

G. Flexural Strength Test

The concrete is prepared at required rate of mass element the mould is filled with concrete in layers and blows 25 times with standard tamping rod. After the day or we can say 24 hours the mould is removed and specimen placed in the water tank for curing at a temperature of 27 + 2 C. Depending upon the requirement the test specimen is removed from the water tank and wipe it properly for 7,14 and 28 days for testing.

Fig -8: Flexural Strength Test 7

Conclusion

Asbestos fiber acted as a reinforcement and hence acted as resistance to the cracks, thus increasing the flexural strength. By replacing the cement with the replacement of cathode ray tubes powder & Coconut Fiber Ash with add Asbestos fiber strengths get increased, also the replacement can be taken into consideration up to certain percentage workability factors gets enhanced as well. The compressive, flexural and tensile strength of the concrete on comparing with conventional concrete gets increased till replacement of 11% cathode ray tubes powder & Coconut Fiber Ash and 0.8% Asbestos fiber was used.

References

[1] Jordi Paya, Lourdes Soriano, “Waste and Supplementary Cementitious Materials in Concrete”, Science Direct, 2018. [2] Laurie Kazan-Allen, “Asbestos: Properties, Uses and Problems”, International Ban Asbestos Secretariat. [3] Robert L. Virta, “Asbestos: Geology, Mineralogy, Mining, and Uses”, USGS. [4] Ayman G. Abdel-Rhaman, Faiz A. M. Mirza, Abdulrahman A. Salah, “An Overview of Fiber Reinforced Concrete, FRC and Fibers Properties and Current Applications”, International Journal of Science and Research, 2019. [5] Zubair R Wani, “Study of Serviceability Limits In Asbestos Fiber RCC Beams”, 2nd international conference on new frontiers of engineering, science, management and humanities, ResearchGate, 2018. [6] MG Alberti, A Enfedaque, JC Gálvez, “The Mechanical Properties & Fracture Behavior of Polyefin Fiber-Reinforced Self-Compacting Concrete” Construction and building materials, Elsevier, Vol. 55, 2014. [7] N.I.M Nadzri, J.B. Shamsul & M.N Mazlee (2012), “Development and properties of composite cement reinforced coconut fiber with the addition of fly ash”, Journal of Sustainable Cement Based Materials, 1(4), 186-191. [8] Sanjay Sen, Rajeev Chandak (2015), “Effect of coconut fibre ash on strength properties of concrete”, Sanjay Sen Int. Journal of Engineering Research and Applications ISSN: 2248-9622, Vol. 5, Issue 4, (Part -1) April 2015, pp.33-35. [9] R Bayuaji, R W Kurniawan, A K Yasin, H AT Fatoni and F M A Lutfi (2016), “The effect of fly ash and coconut fibre ash as cement replacement materials on cement paste strength”, International Conference on Innovation in Engineering and Vocational Education-IOP Conf. Series: Materials Science and Engineering. [10] Baldé, C.; Wang, F.; Kuehr, R.; Huisman, J. The Global e-Waste Monitor–2014; United Nations University: Bonn, Germany, 2015; [11] Singh, N.; Li, J.; Zeng, X. Global responses for recycling waste CRTs in e-waste. Waste Manag. 2016, 57, 187–197. [12] Johnstown, C.E. (Ed.) European Waste Catalogue and Hazardous Waste List; Environmental Protection Agency: Wexford, Ireland, [13] Lee, G.; Poon, C.S.; Wong, Y.L.; Ling, T.C. Effect of recycled fine glass aggregates on the properties of dry-mixed concrete blocks. Const. Build. Mater. 2013, 38, 638–643. [14] Zhao, H.; Poon, C.S.; Ling, T.-C. Utilizing recycled cathode ray tube funnel glass sand as river sand replacement in the high-density concrete. J. Clean. Prod. 2013, 51, 184–190. [15] Romero, D.; James, J.; Mora, R.; Hays, C.D. Study on the mechanical and environmental properties of concrete containing cathode ray tube glass aggregate. Waste Manag. 2013, 33, 1659–1666. [16] Concrete Technology- M.S Shetty [17] Concrete Technology- ML Gambir

Copyright

Copyright © 2024 Sumer Singh, Sourabh Lalotra. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65730

Publish Date : 2024-12-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online